Infrared Leak Detection

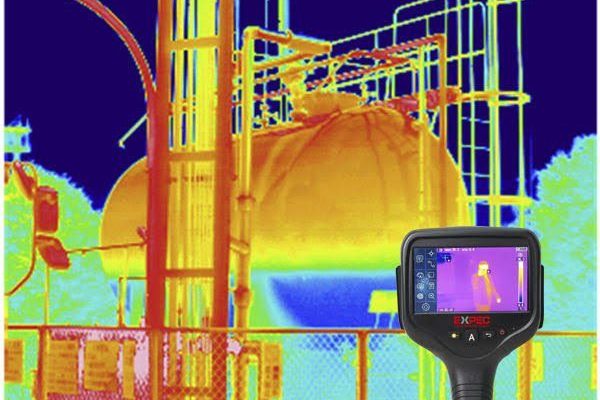

Infrared leak detection is a non-destructive method based on laser technology. Every object emits radiant energy, primarily in the form of infrared radiation, which has a wavelength between 1 to 50 micrometers.

According to ASNT Chapter 12, this method is useful for detecting leaks in shallow underground and above-ground pipelines. It is cost-effective for use in wastewater, steam, oil pipelines, chemical lines, gas pipes, and storage tanks.

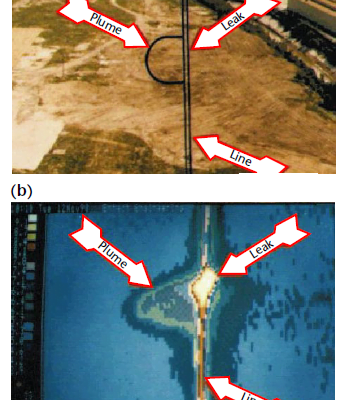

Thermography technology allows for the inspection of large areas with complete coverage. Infrared detection can locate both the leak and any surrounding degradation in the buried pipe's environment.

Types of Infrared Thermography Methods

Thermal infrared leak detection techniques are generally categorized into three methods:

- Infrared Emission Pattern

- Infrared Absorption

- Infrared Photoacoustic Imaging

The first two methods rely on infrared imaging systems, which detect infrared energy emitted by the leak and its effect on the surrounding area or specific infrared frequencies absorbed in the environment. Both methods share several key advantages:

- They are non-contact and non-destructive.

- Suitable for inspecting large areas.

- Efficient in terms of labor and equipment.

- Do not interfere with the pipeline flow.

- Do not alter the surrounding environment.

The third method, photoacoustic imaging, uses an infrared laser at a specific frequency to trigger sound waves from the leak site.

The main difference among these methods lies in the type of leak and the auxiliary equipment used alongside the infrared imaging systems. The first method, based on emission patterns, allows operators to analyze general thermal anomalies over large surfaces using infrared imagers. The second method focuses on the absorption of a specific infrared frequency within the thermal spectrum emitted by an infrared emitter and captured by a combined imaging system, enabling the operator to observe localized blacked-out areas due to energy absorption.

Factors influencing the infrared leak detection method include:

- Temperature of the underground fluid.

- Surface cover temperature.

- Ambient temperature.

Comparison of Laser Leak Detection and Helium Leak Detection

Helium leak detection excels in situations where multiple pipelines with similar temperatures are located next to each other. In these cases, helium leak detection can isolate the target component with high precision, without interference from other components, whereas thermography tends to produce significant errors in such environments.

Helium leak detection is 10 million times more accurate than infrared leak detection. Additionally, helium leak detection has no limitations related to depth, soil composition, or thermal interference, making it far superior in many industrial applications.